1.Automatic Bottle Sleeve Labeling Machine used in Taiwan original technology and design concept from Germany carried out on the improvements made.

2,device uses a large touch screen, easy operation, parameter display glance, truly interactive.

3,Japan Mitsubishi PLC control system, more stable performance.

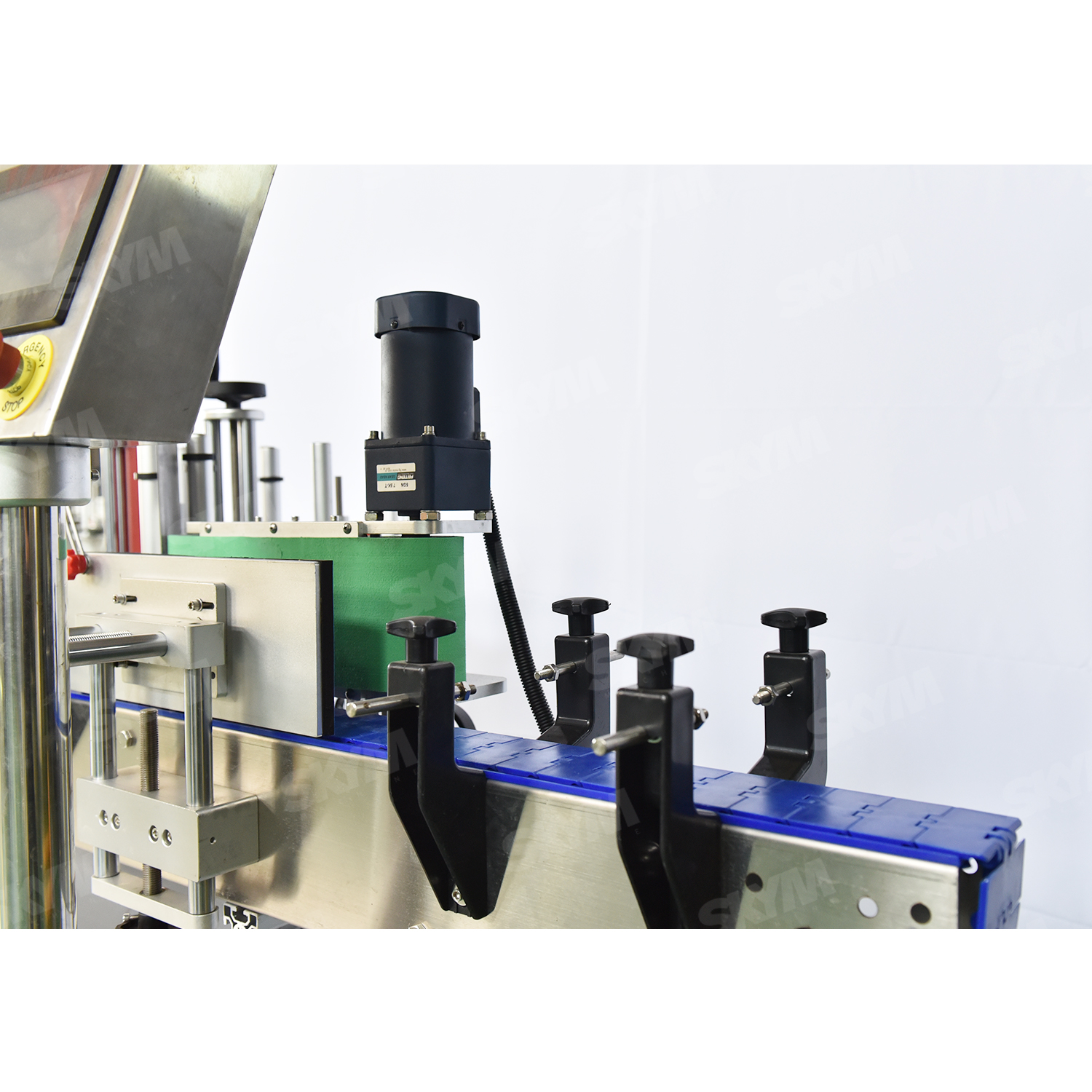

4,measuring objects using Omron photoelectric sensors, sensing objects higher sensitivity.

5,Omron Japan / Taiwan FOTEK label of photoelectric sensors, sensing a sensitive, easy to adjust.

6,using German technology KINCO a standard motor, stable performance, high labeling accuracy.

7,using matching motor drive signal is never distorted.

8,using the French Schneider inverter speed, more stable performance.

9,large control box, the internal electrical heat easier, convenient detection, increase firmness.

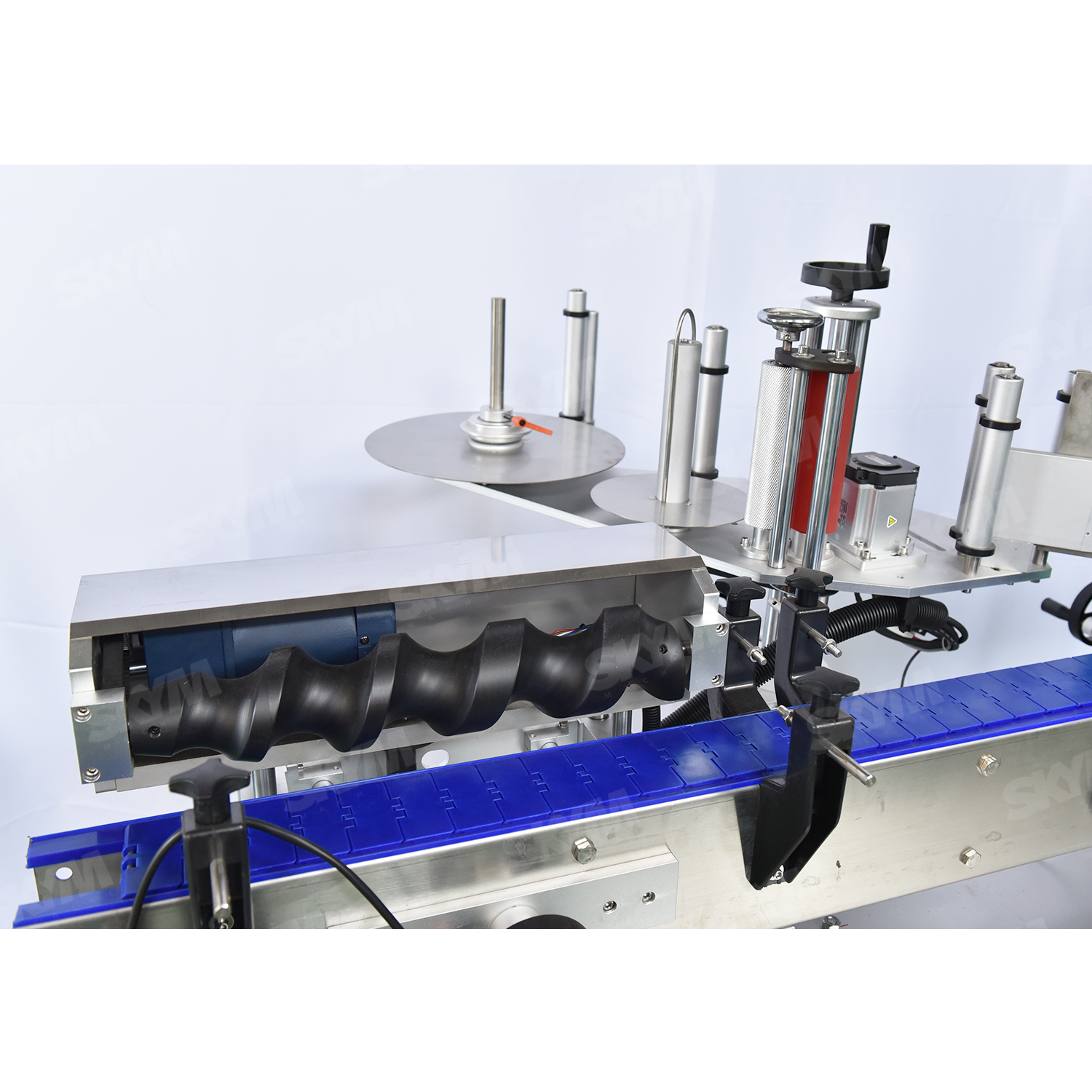

10,high quality stainless steel and aluminum alloy.

11,anodized aluminum surface sandblasted, higher strength, beautiful appearance.

12,send standard buffer device, make sure that the job is not pulled off the label during.

13,closed end of paper patented design to ensure the collection of paper is not pulled off.

14,equipment motor coordination, running smooth and stable, durable, long service life.

15,main electrical components are well-known products, parts by unified action solid resistance and connecting a computer numerical control machine tool precision machining, parts are well protected, prolonged use will not be any problems.